SEALEXCEL INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SEALEXCEL INDIA P.LTD.

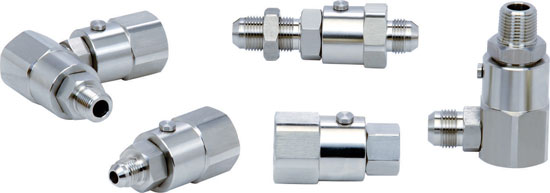

Swivel Joints

SEALEXCEL® Swivels joints have been carefully designed and manufactured with continuous research and development backing to very close tolerances under rigid quality control procedures approved to ISO 9001:2000 quality management systems to meet the requirements of high pressure hydraulic applications, the swivel joints are generally used in various machines/Industries such as,

[Swivel Joints]

OPERATING PARAMETERS

TYPES DESCRIPTION

DESCRIPTION

Available Size

1/4" to 1"

Temperature Rating

Up to 5000 PSI.

End Connections

Up to 180°C (Depending on sealing material)

TYPES DESCRIPTION

• Female BSPP x Female BSPP • Male BSPP x Female BSPP

• Female NPT x Female NPT • Male NPT x Female NPT

• Male JIC 37° x Female NPT • Male JIC 37° x Female JIC 37°

• SAE 'O' Ring Straight x Female NPT • Male JIC 37° Bulkhead x Female JIC 37°

• Male JIC 37° Bulkhead x Male JIC 37° • Male SAE 'O' Ring straight thread x Male JIC 37°

• Male NPT x Male JIC 37° • Male JIC 37° x Male JIC 37°

•Male SAE 'O' Ring straight thread x Female JIC 37°

[Swivel Joints] [Swivel Joints]

• Injection Molding

• Pulp and Paper

• Logging

• Refuse Trucks

• Utility Equipment

• Mobile Equipment

• Hose Reels

• Pressure Washers

• Machine Tools

• Steel Mills

• Palletizers etc.

FEATURES

• Hardened bearing races for extended service life

• Full Flow design minimizes pressure drop for optimum system performance.

• Sealed bearing design isolated bearing race from media and environment.

• Reduced bearing load design minimizes wear in the bearing race and extends services life.

• PTFE back-up rings support primary seal for high-pressure applications.

• Variety of seal option available.

• Available in Steel and Stainless Steel SS 316 Material.

BENEFITS

• Show no significant increase in torque with introduction of pressure

• Fit in compact areas.

• Prevent environmental contaminates from entering the swivel joints.

• Allow quick and reliable field repair.

CONSTRUCTION OF SWIVEL JOINTS

[Swivel Joints]

MATERIAL OF CONSTRUCTION

Metal Parts

• Carbon steel with Zinc plating : It is recommended for

non-corrosive applications i.e., hydraulic,

pneumatic etc.

• Stainless Steel : It is recommended for applications i.e.

water, chemicals, solvents etc.

Sealing Parts

• Viton® (Fluorocarbon) -

For petroleum based applications.

• Aflas® (TetraFluoroethylene-Propylene Copolymer)

form any individual chemicals.

• PTFE (Teflon®) : used as a back-up ring.

Other seals such as Nitrile, Silicon, EPDM are available on request.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.